LM-8A CNC Slant Bed Lathe

Machine may be shown with optional accessories.

LM-8A is a high precision CNC Lathe constructed in one-unity shaped base structure to enhance machine stability and maximize cutting rigidity.

- A2-6 spindle nose

- 15" (380 mm) maximum turning diameter

- 15.4" (390 mm) maximum turning length

- Programmable hydraulic tailstock

- High precision ballscrew and linear guide

- Dynamic graphic display

- High speed 12-station servo turret

- 1,181 ipm rapid traverse

- 4,500 rpm spindle speed

- 563 rpm spindle speed of full power output

Features

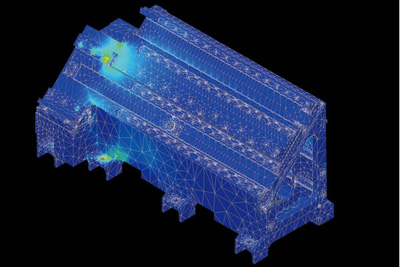

Rugged and Stable Base

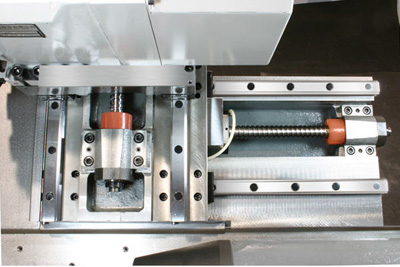

High Precision Ball Screw and Linear Guide

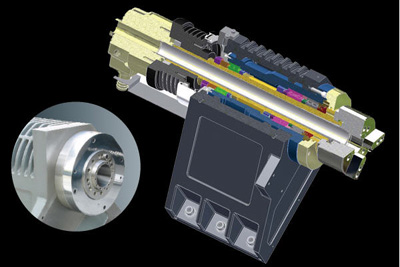

Rigid and Precise Spindle

Spindle front side is supported by large diameter roller bearings and angular contact ball bearing. Optimal span and balancing support between the front and rear roller bearings resists the radial load and provides excellent cutting conditions in high and low speed. Heavy-duty headstock utilizes heat symmetrical and dissipation slot design to reduce thermal deformation and increase cutting accuracy.

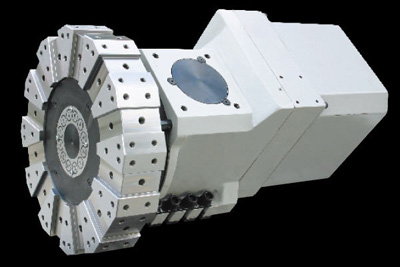

High Speed Servo Turret

Programmable Hydraulic Tailstock

Accessories

STANDARD ACCESSORIES:

- 8" 3-jaw hydraulic chuck

- 12-station servo turret

- Fully enclosed splash guard

- Work light

- Warning light

- Hydraulic system

- Coolant system

- Auto lubrication system

- Chain type chip conveyor with chip cart

- Tool kit

- Leveling bolts and pads

- Cutting tool holders (6 pieces)

- Boring bar holders (6 pieces)

- Boring bar bushing (1 set)

- Driller bushing (1 set)

Specifications

| MACHINE | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model: | LM-8A | ||||||||

| Type: | CNC Slant Bed Lathe | ||||||||

| CNC controller: | Fanuc Oi-TD | ||||||||

| CAPACITY | |||||||||

| Swing over bed: | 18.1" | ||||||||

| Swing over cross slide: | 8.2" | ||||||||

| Standard turning diameter: | 7.9" | ||||||||

| Max. turning diameter: | 15" | ||||||||

| Max. turning length: | 15.4" | ||||||||

| Distance between centers: | 20.7" | ||||||||

| TRAVEL | |||||||||

| X-axis travel: | 8.3" (7.9" + 0.4") | ||||||||

| Z-axis travel: | 15.4" | ||||||||

| Guide way: | Linear guides | ||||||||

| SPINDLE | |||||||||

| Spindle nose: | A2-6 | ||||||||

| Spindle bearing diameter: | 3.9" | ||||||||

| Max. spindle speed: | 4,500 rpm | ||||||||

| Spindle bore: | 2.4" | ||||||||

| Draw tube bore: | 2" | ||||||||

| Chuck size: | 8" 3-jaw hydraulic chuck | ||||||||

| TURRET | |||||||||

| Turret type: | Inch/mm | ||||||||

| Driven way: | Servo motor | ||||||||

| Number of tools: | 12 | ||||||||

| Tool shank size: | â–¡0.79" | ||||||||

| Max. boring bar diameter: | ø1.26" | ||||||||

| TAILSTOCK | |||||||||

| Driven way: | Programmable hydraulic | ||||||||

| Tailstock taper center: | M.T. #4 | ||||||||

| Travel: | 17.3" | ||||||||

| FEEDRATE | |||||||||

| X-axis rapid feederate: | 1,181 ipm | ||||||||

| Z-axis rapid feederate: | 1,181 ipm | ||||||||

| Cutting feedrate: | 49.6 ipm | ||||||||

| SERVO MOTOR | |||||||||

| Spindle motor: | 10/12 HP | ||||||||

| Spindle speed (full power output): | 563 rpm | ||||||||

| X-axis motor: | 1.2kW | ||||||||

| Z-axis motor: | 1.8kW | ||||||||

| Servo motor: | 0.67 HP | ||||||||

| COOLANT TANK | |||||||||

| Tank capacity: | 150L | ||||||||

| MOTOR | |||||||||

| Chip conveyor motor: | 0.25 HP | ||||||||

| Coolant pump motor: | 0.93 HP | ||||||||

| Hydraulic pump motor: | 2 HP | ||||||||

| WEIGHT & DIMENSIONS | |||||||||

| Floor space (LxWxH): | 120" x 90" x 89" | ||||||||

| Net weight: | 6,660 lb. | ||||||||

| Gross weight: | 7,700 lb. | ||||||||

* Design and specifications are subject to change without notice.

Machine may be shown with optional accessories