TM-40 Universal Tool and Cutter Grinder

Machine may be shown with optional accessories.

Victor TM-40 Universal Tool & Cutter Grinder can perform a wide range of work. In addition to almost limitless application as a tool sharpener, TM-40 can also be adapted to light cylindrical, surface and internal grinding operations. A wide selection of attachments permits you to extend the versatility of the basic machine to suit your specific needs.

FEATURES:

- Versatility

- A wide selection of optional attachments

- Universal workhead

- Tilting and swiveling wheelhead

- 2 HP grinding wheel motor

Features

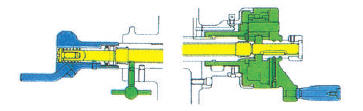

Inclination of Wheelhead

The wheelhead can easily tilt up to ±15° with a 360° swivel on the horizontal plane. The wheelhead can grind at any angle.

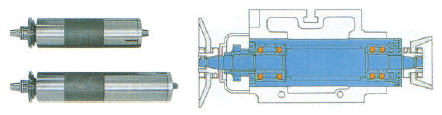

Two pairs of angular contact balls are designed to support the spindle bearing and tighten by nuts. The inner of the wheel spindle has been greased with lubricant, therefore, no additional lubricant is needed.

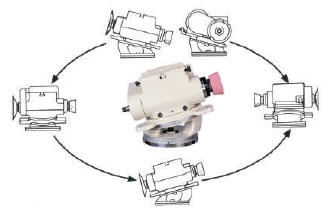

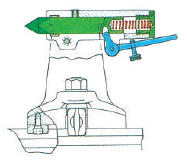

Universal Workhead

The workhead can rotate and adjust accurately at any angle, in either horizontal or vertical position. The spindle had a taper on both ends - NT #50 and MT #5. It can increase working efficiency by using various collets.

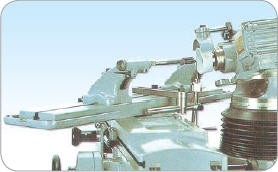

Working

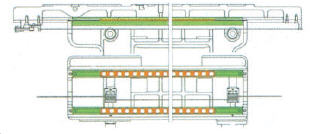

Table

The working table can rotate 120° with ±60° graduated scale attached. At the same time, the workhead can rotate 360° to grind various cutting tools.

Precise Ball Groove of Conformation

Clutch

The feed of the working table can control various speeds both high and low. The working table has a feed knob on both sides. The clutch handle on the right-hand side controls at a lower speed to prevent the interruption of its precision.

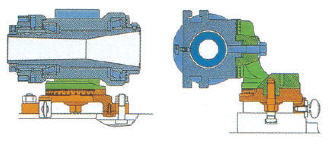

Tailstock

Right-hand tailstock (standard) and left-hand tailstock (optional) - one is fixed by the bolt while another one is fixed by spring pressure. The combination of tailstocks and workhead works very well at steadily holding the workpiece to achieve the best grinding results.

Right-hand tailstock Optional left-hand tailstock

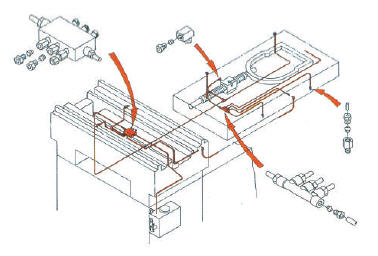

Centralized Lubrication

Accessories

STANDARD ACCESSORIES:

- Leveling blocks

- Workhead

- Right-hand tailstock

- Center gauge

- Ejector rod

- Center for workhead spindle MT5

- Diamond dresser holder

- Grinding wheel washer set

- Wheel guard (max. Ø 3.54")

- Wheel guard (max. Ø 4.33")

- Wheel guard (max. Ø 4.92")

- Wheel guard (max. Ø 5.91")

- Wheel guard holder (short)

- Wheel guard holder (long)

- 2 sets of grinding wheel flanges

- 4" grinding wheel flange extension (Ø 1.25")

- Grinding wheel (WA 90D x 38T x 31.75H)

- Grinding wheel (GC 125D x 38T x 31.75H)

- Grinding wheel (WA 150D x 13T x 31.75H)

- Grinding wheel (GC 150D x 13T x 31.75H)

- Grinding wheel (WA 150D x 19T x 31.75H)

- Draw-in bolt for workhead and spacer

- Wheel spanner

- Collet wrench

- Fixture rod

- Open end wrench

- Combination wrench (19 mm)

- Combination wrench (24 mm)

- Toolbox and adjusting tool

Specifications

| MACHINE | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model: | TM-40 | ||||||||

| Type: | Universal Tool & Cutter Grinder | ||||||||

| STROKE | |||||||||

| Longitudinal movement of table (x-axis): | 15.75" | ||||||||

| Cross movement of saddle (y-axis): | 9.84" | ||||||||

| Vertical movement of wheelhead (z-axis): | 9.84" | ||||||||

| Distance between centers: | 27.56" | ||||||||

| Distance between tailstock and workhead : | 22.83" | ||||||||

| Workhead taper: | One end MT5 / the other NT50 | ||||||||

| WORKBENCH | |||||||||

| T-slot: | 0.59" (+0.00197" ~ +0.00394") | ||||||||

| Working range of table: | 5.31" x 37" | ||||||||

| Rotative angle of table: | ±60° | ||||||||

| JOG adjustment of table: | ±10° | ||||||||

| WHEELHEAD | |||||||||

| Inclination of wheelhead: | ±15° | ||||||||

| Rotative angle of wheelhead: | 360° | ||||||||

| Distance between centers of spindle and table: | Max. 11.81" / Min. 1.97" | ||||||||

| Distance between centers of spindle and T-slot: | Max. 16.34" / Min. 6.50" | ||||||||

| Peak power: | 2 HP 3 Phase | ||||||||

| Grinding wheel spindle speed: | 2600, 3700, 6200 rpm | ||||||||

| WEIGHT & DIMENSIONS | |||||||||

| Dimensions (LxWxH): | 68.31" x 61" x 58.27" | ||||||||

| Weight: | 2,140 lb. | ||||||||

* Design and specifications are subject to change without notice.

Machine may be shown with optional accessories