FHR-68e Digital Threading Chucking Machine (Discontinued)

Machine may be shown with optional accessories.

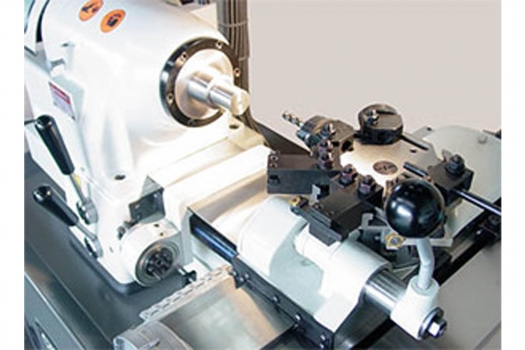

Super-precision Digital Threading Technology chucking lathe comes with a smooth 3 HP frequency controlled motor that runs virtually vibration free and extremely quiet. Easy to use LCD touchscreen to simplify threading operations by selecting target TPI or mm pitch on the screen. DRO capabilities are built-in as standard. Victor FHR-68e chucking lathe is built with extreme precision and performance in mind.

- Digital Threading operations are microprocessor controlled and carried out by synchronized spindle speed and servo motor feed

- LCD touchscreen to select thread pitch (TPI or mm) with no gears to change

- DRO functions integrated into LCD panel features linear scales on X and Z axis

- 14" maximum distance from face of turret to spindle

- The spindle is mounted in high precision preloaded angular contact ball bearings

- Infinitely variable spindle speeds from 0 ~ 4,000 rpm

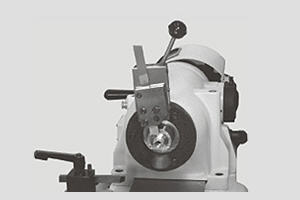

- Fast lever collet chucking with a single movement

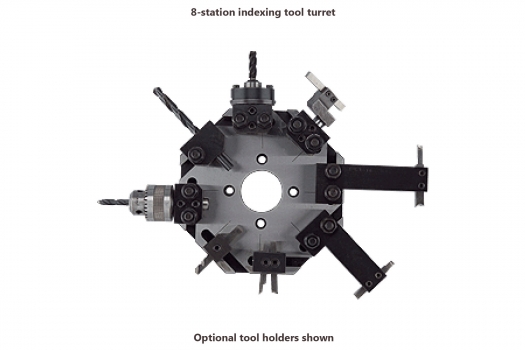

- Preloaded ball bearing 8-station turret with indexing lever

- Solid hardened and ground alloy tool steel bed

- Independent electric variable speed

- Full bearing carriage with Turcite-B slideway bearing surface

- Hi/Low speed quick change lever for convenience

- 5C lever type collet closer standard

- 3 HP frequency controlled motor (inverter drive)

Features

Accessories

STANDARD ACCESSORIES:

- LCD touchscreen with digital threading system

- DRO functions integrated into the LCD touchscreen

- Variable frequency drive

- 5C lever type collet closer

- 6" 3-jaw scroll chuck with back plate

- 8-station turret with indexing lever

- 8-position carriage stop

- Halogen work light

- Coolant system

- Leveling screws and pads

- Manual and parts list

OPTIONAL ACCESSORIES:

5C collet fixture plate

Fixture plate

Boring tool holder

Boring tool holder (20 mm dia.)

Drill and shank tool holder

Extension tool holder

Tool holder extension

Tool setting gage

Straight and taper turning slide for double tool cross slide

Double tool cross slide

Vertical cut-off slide without cut-off blade

Chip and coolant shield

Single tool holder

Double tool holder

Triple tool holder

Adjustable tool holder

Multiple tool holder (front or rear)

Face plate

Knurling holder

Slide tool

Quick-acting recessing tool

Adjustable rotary stop

Releasing die nut holder

Releasing tap holder

Centering and facing tool

Knee tool

Releasing tap holder (collet type)

Tool holder collet (collet type)

Adjustable holder

Quick-change adjustable holder

Square shank tool holder (right/left hand)

Expanding collet and pad

Drill chuck arbor

Drill chuck

Angle plate

Threaded positive stops

Universal collet stop

Bed adapter for double tool cross slide

Specifications

| MACHINE | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model: | FHR-68e | ||||||||

| Type: | Digital Threading Technology Chucking Machine | ||||||||

| SPINDLE CAPACITY | |||||||||

| With jaw chucks: | 6" | ||||||||

| With expanding collets: | 3" | ||||||||

| With round 5C collets: | 1-1/16" | ||||||||

| With hexagon 5C collets: | 7/8" | ||||||||

| With square 5C collets: | 3/4" | ||||||||

| With step chucks: | 1-1/16" ~ 6" | ||||||||

| Spindle nose diameter: | 2.189" | ||||||||

| Spindle nose I.D. / O.D.: | 5C / Chuck with 4º taper (5C / 2-3/16"-10 TPI) | ||||||||

| Hole through spindle: | 1-1/4" | ||||||||

| Variable spindle speeds: | 0 ~ 4,000 rpm (5C collet) | ||||||||

| CAPACITY | |||||||||

| Swing over bed: | 12.992" | ||||||||

| Max. fixture diameter: | 9" | ||||||||

| Max. distance from face of turret to spindle: | 14" | ||||||||

| THREADS, FEEDS & TRAVELS | |||||||||

| Carriage power feed range: | 0.236" ~ 9.842" (variable) | ||||||||

| Cross slide power feed range: | 0.354" ~ 6.299" (variable) | ||||||||

| Cross slide travel: | 4.488" | ||||||||

| Inch threads: | 4 ~ 120 TPI (digital threading system) | ||||||||

| Metric threads: | 0.2 ~ 6.35 mm (digital threading system) | ||||||||

| POWER | |||||||||

| Inverter spindle motor: | 3 HP 220V 3PH | ||||||||

| Coolant pump: | 1/8 HP 220V 3PH | ||||||||

| Feed inverter motor: | 1/2 HP | ||||||||

| WEIGHT & DIMENSIONS | |||||||||

| Machine dimensions (LxWxH): | 74"x34"x74" | ||||||||

| Gross weight: | 2,420 lb. | ||||||||

* Design and specifications are subject to change without notice.

Machine may be shown with optional accessories